Dry Box Provides a wide range of shipping container modifications designed to meet your specific requirements. If your family or growing business has a need and you think a modified shipping container might be the right solution we want to hear about it. With over a Decade of successful container projects completed, Dry Box is here to help you turn your idea into Reality. Our modification staff can guide you through the process, recommend solutions to the specific challenges of Cargo Container Construction and more than likely provide sample pictures of past similar projects.

For those do it your selfers Dry Box now offers Container modification accessories that you can order and pick up at our modification shop or have direct shipped directly to you.

Designed to specifically fit our 1 trip Container Factory Block lock Boxes. No other lock on the market fits better or function more reliablily than out Block Lock. Comes with 3 Keys.

The Number 1 theft deterrent is Our High security lock box, constructed of 4” x 6” x ¼” tube steel with a 2” x 3/8th thick lock tab drilled to accommodate a 3/8” shank case hardened lock. Our Lock box is welded on the right-hand door and overlaps the tab welded on the left-hand door and virtually locks the doors together. The Lock box prevents bolt cutters or grinder from reaching the lock inside it.

Note: Installation requires welding.

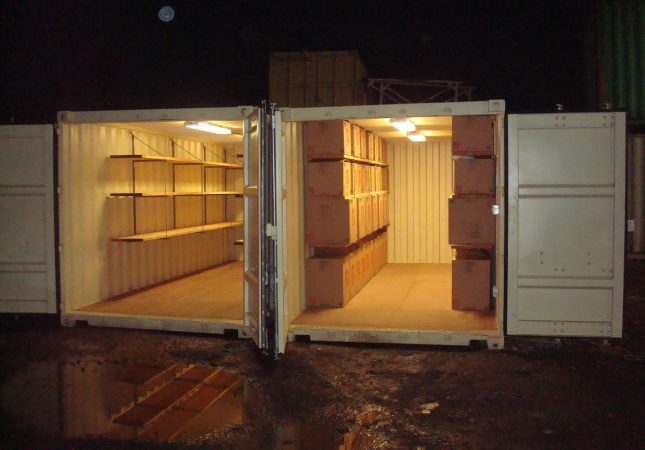

Our hanging Shelf Brackets hang from the upper tie down loops inside a container. The Brackets Install quickly, requires minimum of 2 brackets to form a shelf. Once Brackets are hanging insert 2 each 2 x 20 planks per level and hinge into place. Our hanging brackets are designed to save vertical shelf space. Requires a minimum 2 man crew and can install full length shelving in under 15 minutes.

Note: Customer must supply his own 2” x 10” planks and cut to length.

We offer a wide range or prefabricated frames all you do is cut a whole insert our prefabricated frames and weld in in position. Our tube steel frames create a continues welding surface to mate to the corrugated panels of the container creating a clean finished look on both the inside and outside of the container.

We now have door frames and door frame and door kits in stock in stock available in 2” x 3” and 2” x 4” tube steel frame. When purchasing a door kit please indicate swing in and swing out direction and hinge right or hinge left orientation. Our tube steel frames create a continues welding surface to mate to the corrugated panels of the container creating a clean finished look on both the inside and outside of the container.

Note: Installation requires welding.

In stock 12” x 12” louvered vents installed in a 2” x 2” tube steel frame, simple cut a hole, Insert and weld in position. Our tube steel frames create a continues welding surface to mate to the corrugated panels of the container creating a clean finished look on both the inside and outside of the container. Ask about other custom order sizes.

Note: Installation requires welding.

Our window frames can be purchased in 2” x 3” or 2” x 4” tube steel construction. All frames have mitered corners for a quality finished look. Custom frames can be special ordered by request.

Note: The above windows do not meet egress requirements. Never install Bars on an egress window.

Note: Installation requires welding.

Our prefabricated air conditioning cage will make you look like a pro. Simple cut a hole, insert our cage and weld in position. Our tube steel frames create a continues welding surface to mate to the corrugated panels of the container creating a clean finished look on both the inside and outside of the container.

Stacking cones help keep stacked containers in horizontal position in a stack, prevents containers from being knocked out of position during high wind or accidental shifts during container stacking and handling. Stacking cones only prevent lateral shift and do not lock a container vertically down or lock vertically to another Container. Each container requires 4 stacking cones.

For safe vertical stacking of shipping containers, use these twist lock stacking pins. The pins are designed to interlock stacked shipping containers in both vertical and horizontal direction. Containers are locked together after turning the twist lock action handles.

Used to connect shipping containers to each other, use these bridge clamps. They are designed to securely connect empty or loaded shipping containers horizontally and are made to fit into container corner castings. Each container requires 4 bridge fittings for safe horizontal connections.

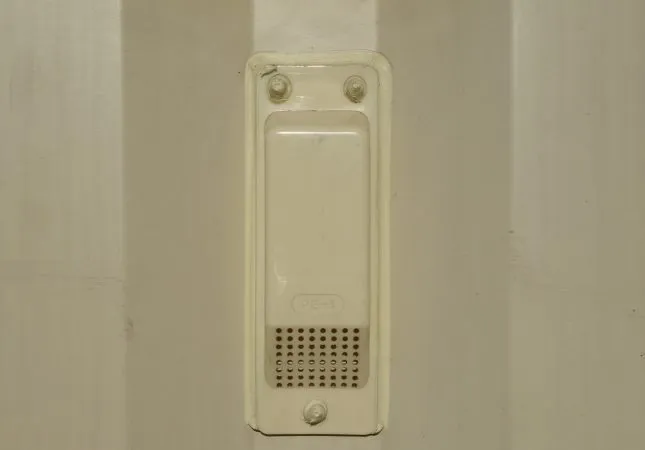

Replacing that damaged Factory style container vent does not have to be complicated, simply replace with our OEM style vent.

Yard Address

2021 E Marc St

Tacoma, WA 98421

Cell: 206-339-8309

Office: 253-272-0902

Branch Manager, Aaron Norlin

aaron@drybox.com

Yard Address

14631 N

Bybee Lake Ct

Portland OR 97203

Cell: 503-822-7550

Office: 503-946-9744

Branch Manager, Wayne Vigre

wayne@drybox.com

Yard Address

2820

W 500 S

Salt Lake City, UT 84104

Cell: 801-515-2875

Office:801-505-0002

Branch Manager, Clarence Wright

clarence@drybox.com

Yard Address

8414

W Geiger Blvd

Spokane, WA 99224

Cell: 509-496-8704

Office: 509-606-2699

Branch Manager, Ryan Earle

ryan@drybox.com

Yard Address

421

Keys Rd.

Yakima, WA 98901

Office: 509-209-9856

Branch Manager, Rafael Brambila

rafael.b@drybox.com

Office Address

6328 Barton Rd

Plant City, FL 33565

Cell: 360-880-0612

Branch Manager, Cody Pennington

codyp@drybox.com