What are the Most Common Shipping Container Repairs?

When you think of a shipping container, you picture a steel box that looks like it’s indestructible. But while they are certainly durable and strong, they are still vulnerable to wear and tear, rust, and other forms of damage. Here’s a look at the most common shipping container repairs that people have to make to their shipping containers.

1. Rust

Older containers can show signs of rust, especially in areas of damage like dents and scratches. Anywhere the paint job has been compromised, rust can take hold. Once rust is present, it can actually grow underneath the paintwork. It just needs an entry point. That’s why protective paintwork is so important.

Certain sections of shipping containers are more vulnerable to rust, such as:

- Welds

- Seams

- Bottoms of doors

- Container sides at the ground

- Damaged sections

Flaking paint on containers that have been exposed to the sun and sea will quickly develop rust patches. It’s usually just surface rust that can be removed with some sandblasting, followed by priming and repainting.

But for deep rust and holes, those will have to be cut out so the rust doesn’t spread to healthy areas. A new piece of steel can be welded onto the container to patch up the hole. Always inspect your container periodically for rust so you can perform touchups.

2. Damaged or Rotting Flooring

Shipping container floors are usually comprised of one-inch-thick marine grade plywood that is quite durable but that will experience wear and tear over the years. Flooring takes the brunt of punishment because it sees a lot of foot traffic and machinery traffic – not to mention it has to carry the loads placed in the container.

Container floors experience a lot of gouging, scraping, pressure, and weight, which can lead to water damage if not sealed properly. You can replace the flooring fairly cost effectively.

3. Replacement of Door Seals

If you are storing goods in your container, you want it to be airtight and watertight to protect the items from weather, dirt, dust and pests. While the rest of the container could be in great condition, if the rubber seals on the doors are worn out and old, your container will be compromised.

In this case, you will have to replace the rubber seals. Check the doors themselves regularly, as they could get warped if they have been knocked or dented. You may have to repair or replace those warped doors so they close properly. Lubricate the hinges regularly too.

4. Repainting

Freshly painted containers look great. But they can also add another layer of protection. Along with rust removal, hole patching, and sandblasting flaking paint, your container could be looking like new in no time. The exterior isn’t the only thing you should paint – don’t forget about the interior too.

You may also want to repaint your recently purchased shipping container so as to cover up previous branding and markings from the company before. Once it’s repainted, you can add your own branding and logo to the sides of the container.

5. Refrigerated Containers

The same shipping container repairs that standard containers fall victim to are the same ones that refrigerated containers – or reefers – need as well. Refrigerated containers are kept cool to preserve anything from food to flowers to pharmaceuticals. The walls, ceilings and floors of refrigerated containers need regular care and repair. But with reefers, they have extra components that can require some TLC – mainly to the refrigeration unit.

If you are experiencing issues with refrigeration, you will have to call a professional to troubleshoot and diagnose the problem. Don’t attempt to fix it on your own. Reefers need to be sealed well at all times, so always make sure the door seals are tight. Address any rust spots as they crop up, which will enhance energy efficiency and reduce operational costs.

If the container doesn’t stay cool, your refrigeration mechanic can make the necessary repairs or replace the whole unit if it is old.

6. Preventative Maintenance

Preventative maintenance is your best bet when it comes to caring for your shipping container. Regular inspections, repairs and touch-ups can keep a small issue from becoming a large one with a lot of expense and hassle. It’s not difficult maintaining a shipping container. It just takes patience, diligence and time.

Frequently Asked Questions About Repairing Containers

Can shipping containers be repaired?

Absolutely! Like most structures, shipping containers can be repaired. Whether they have dents, holes, or rust, there are ways to restore them to their original condition or even improve them.

How do you repair a hole in a shipping container?

Repairing a hole in a shipping container involves a few steps:

- Clean the Area: Start by removing any rust or debris around the hole using a wire brush.

- Cut Out the Damaged Section: Use an angle grinder or metal saw to carefully remove the damaged section.

- Weld In a New Patch: Once the damaged area is removed, place a metal patch over the hole and weld it in place.

- Seal and Paint: After welding, apply a rust-resistant primer and paint to protect the repair.

How do you fix a rusty shipping container?

To address rust on a shipping container:

- Remove the Rust: Use a wire brush, sandpaper, or a grinder to remove the rusted areas.

- Clean the Area: Wipe away any debris or dust.

- Apply Rust Converter: This converts rust into a protective layer.

- Paint: Use rust-inhibiting paint to provide an extra layer of protection.

What to do when a container is damaged?

If a container is damaged:

- Document the damage with photos.

- Inform the supplier or leasing company promptly.

- Determine if it’s safe to continue using the container.

- Get estimates for repairs if you’re responsible for them.

Who is responsible if a container is damaged?

Responsibility for damage depends on the terms of the rental, lease, or purchase agreement. If rented or leased, the lessee might be responsible unless damage occurred prior to possession or if it’s due to natural wear and tear. Always review contracts to understand liability terms.

What are the most common types of container damage?

The most frequent container damages include:

- Dents or Bends: Often due to mishandling during transport.

- Rust: This can result from exposure to the elements.

- Damaged Door Seals: Leading to potential water leaks.

- Floor Damage: Often from overloading or spillage inside the container.

- Punctures or Holes: From forceful impacts or severe corrosion.

What is the weakest part of a shipping container?

The weakest parts of a shipping container tend to be the doors and the door seals. While the corrugated walls provide strength and resilience, the doors, especially the seals and locking mechanisms, are more susceptible to wear and tear, damage, and potential leaks. Regular maintenance and checks are crucial to ensure they remain in good condition.

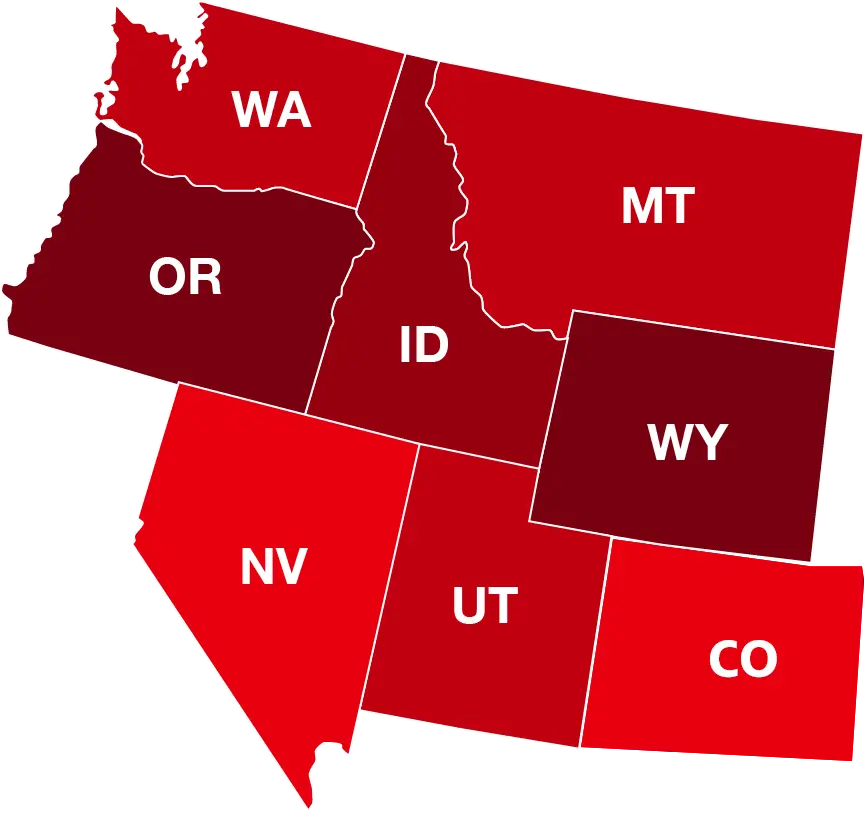

Contact DRY BOX

To get a free quote on your new or used shipping container, contact us toll free at 866-549-9823.