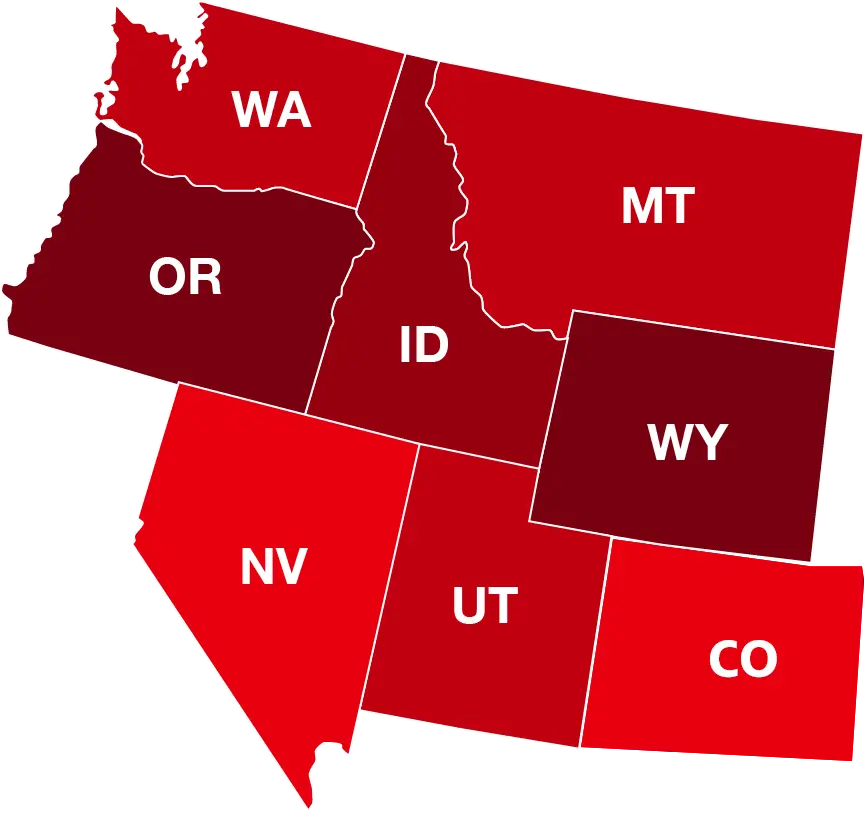

Top Ways to Protect Your Container in the PNW

If you have recently purchased a shipping container in the Pacific Northwest, whether Washington, Oregon or another nearby state, you’ll understandably want to ensure it stays protected from the elements. That’s why you should place a high priority on maintenance and TLC.

Upon purchasing your shipping container, you should have it surveyed for existing damage such as holes, odors, ventilation, cleanliness, temperature control, and flooring. Such inspections are very important, as they can impact the health of the goods in your container.

Types of Container Damage

There are many kinds of damage that can happen to your shipping container. Here are some of the most common ones:

- Broken doors and locks: This often results from poor handling and being irresponsible in regards to loading, thefts or traffic accidents.

- Total loss of a container when on board the ship: This usually happens when the ship is rolling back and forth due to storms at sea. Improperly-stacked containers featuring incorrectly-claimed weights and improper cargo stowage can also create damage.

- Dented and scratched container: This happens with poor forklift handling, traffic accidents, and scraping of your container against others. There’s also a risk of your container being dropped due to a malfunctioning forklift, sloppy loading or overload unit.

- Heat damage: Fires on board can harm your shipping container.

- Holes: This is caused by improper forklift handling, or due to a collision by a vehicle or other container.

- Rail and road accidents: Bad weather, poor road conditions, poor stowage, and driver fatigue can all cause damage. In addition, train derailing happens when drivers are too tired, when there are faulty railroad tracks, when there’s bad weather, and when someone is speeding.

How to Address Damage

If your container has experienced damage, here’s what you can do:

- Once your container is delivered, hire a surveyor to inspect it and see if there are any signs of damage.

- Snap photos of any damage and send an invoice. If the quoted amount is less than the value you agreed on, the supplier will have to pay for the damage.

- The responsible party will have to pay up, after the invoice and the fees are determined.

- Follow up with all parties about payment for the damage.

A container damage survey lets you know how extensive and expensive the repairs will be so you can quickly determine damage claims and understand how much you will have to pay.

You should always perform frequent container damage surveys so you can stay informed about all repairs and maintenance. This will also ensure a long lifespan of your container and ensure that it is in optimal condition, and will help to reduce the damage claims.

It’s important to have your container inspected before you sign on the dotted line for rentals or purchases. You need to have a clear understanding of the container’s condition before you put it to use.

Keeping Rust Off Your Container

The biggest type of damage is rust. That’s why we want to devote a whole section to rust and how you can keep it off your container.

Shipping container rust happens due to oxidation when it comes into contact with moisture. When you don’t fix dings and dents, you encourage the formation of rust due to loss of the protective paint layer. Protect your container from water damage and always fix dents right away to improve the look of the container as well as its lifespan.

Here’s how you can prevent rust from occurring.

1. Keep Your Container Dry

Keep your container far away from water and the elements. The ground and trees can infiltrate your container with water, which spreads rust.

2. Place a Tarp On It

Drape a thick plastic tarp over the container when you aren’t using it, particularly in rainy or snowy climates, to protect against exposure to anything from snow and rain to hail and heavy winds. Wind can easily make branches and rocks fly into your container, piercing it or denting it. To still use your container while offering plenty of protection, put a tarp over the unit, sort of like a tent.

3. Keep it Off the Ground

Prop up your container on a foundation, like railroad ties or concrete slab. This will ensure the bottom doesn’t come into contact with water from sand, dirt, gravel, or grass. Even bugs can be detrimental to containers. This also goes a long way toward ensuring air flow can’t occur under the container.

4. Gable the Roof

Because older shipping containers can have small dents on the roof (they get stacked during overseas transport), water can pool in these concave dents. As you can imagine, this leads to rust. You can prevent this from happening by placing a 4×4 wood plank at the lowest point of the roof. Then push it into the ceiling utilizing a jack. With the water able to roll off, you won’t get pooling and rust.

5. Pressure Wash the Mud Away

Because mud can get caked on your container, you need to regularly wash it all off. Use a pressure washer or a hose to get it off on a regular basis. If you’re planning to paint your container soon, this is a good prep job.

6. Remove Surface Rust Immediately

Because surface rust has not reached the internal layer, you can still clean it and treat it. When left untreated, holes will eventually form. When there is minimal rust, you can easily scrape it away utilizing a wire brush. Follow that up with a damp cloth to wipe away the resulting particles.

Contact DRY BOX

Here at Drybox, we cater to customers in many states throughout the Pacific Northwest. To learn more about our container sizes and prices, feel free to contact us for a free quote.