Best Shipping Container Insulation Options

Shipping containers are strong, secure, and built to handle harsh environments. That strength is exactly why they are used for offices, storage, workshops, and even living spaces.

But steel has one drawback: it transfers heat and cold fast. Without the right shipping container insulation, the inside can turn into a sauna in summer and an ice chest in winter.

A well-insulated container stays more comfortable, better protects stored items, and helps your HVAC system work better. It also reduces condensation, which is one of the biggest things to watch for in steel structures.

If you want a dependable, temperature-controlled shipping container that performs year-round, then installing insulation is one of the smartest upgrades you can make.

In this guide, we will cover the most effective types of insulation for shipping containers, the best installation methods, and the top insulation systems offered at Dry Box.

Why Insulating a Shipping Container is Important

Steel containers react quickly to outside temperatures. That creates uncomfortable conditions and can lead to moisture problems inside.

Here's why insulated shipping containers are so valuable:

- Better temperature control in hot and cold climates

- Reduces risk of condensation, which reduces rust and mold risk

- Lower energy usage when heating or cooling the space

- More usable interior space year-round

- Improved protection for temperature sensitive products, tools, and equipment

- Better sound control for workspaces and offices

If you are building out a container for work or occupancy, insulation for shipping container projects is not an optional upgrade, but rather

the foundation for comfort and performance.

Use cases where shipping container insulation is valuable:

Almost every container application benefits from insulation. The more sensitive your use is to heat, cold, moisture, or noise, the more

important it becomes.

Common use cases for an insulated shipping container include:

- Container office for job sites or remote properties

- Container sheds and workshops

- Storage for temperature-sensitive goods

- Portable retail or pop-up shops

- Gym containers for year-round workouts

- Guard shacks and security booths

- Hunting cabins and weekend shelters

- Farm and ranch utility containers

- Tool and equipment storage for contractors

- Music studios or content rooms that need soundproof insulation

Even if you are not adding HVAC, proper insulation makes the interior feel more stable and liveable.

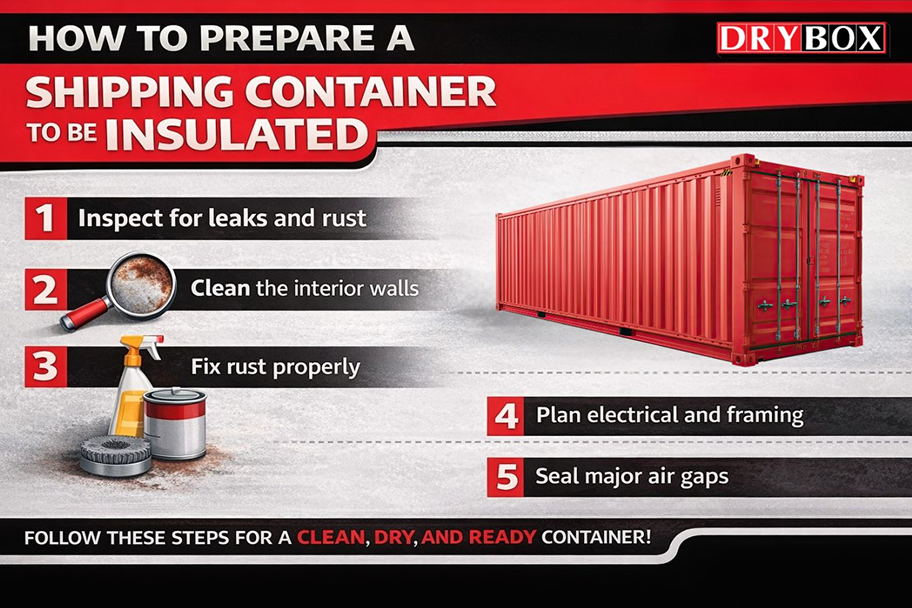

How to Prepare a Shipping Container to be Insulated

Before installing shipping container insulation, you want the container clean, dry, and ready for the build. Skipping prep work can lead to trapped moisture and long-term issues.

Step-by-step prep checklist:

- Inspect for leaks and rust

- Clean the interior walls

- Fix rust properly

- Plan electrical, framing and plumbing

- Seal major air gaps

This preparation step is a big reason why professionally built Insulated shipping containers perform better over time.

How to Insulate a Shipping Container

If you are wondering how to insulate a shipping container, the process is fairly straightforward, but the details matter. Your insulation needs to handle moisture, airflow, and steel surfaces.

Basic insulation steps

-

Choose your insulation type

- Foam board, mineral wool, or spray foam are common options

-

Create a thermal break

- Framing can reduce steel-to-steel contact

- This improves overall insulation performance

-

Install insulation with full coverage

- Gaps reduce effectiveness and can create condensation points

-

Add a vapor control strategy

- This depends on insulation type and local climate

- Proper container ventilation

-

Finish interior surfaces

- Plywood, metal liner panels, or drywall are common finishes

The right container insulation strategy does more than slow heat transfer. It protects the container long-term.

Condensation Control in Shipping Container Insulation

Condensation is one of the biggest issues when insulating a shipping container because it happens when warm, humid air touches cold steel and turns into moisture.

Sealing gaps around doors, seams, and wall cavities helps stop humid air from circulating where it should not. Ventilation also matters, especially if people will be inside regularly.

This is why spray foam insulation for shipping containers is so popular, since it insulates and air-seals at the same time. When done properly, closed cell spray foam insulation creates a vapor barrier and can prevent condensation in shipping containers.

Choosing the Right R-value for Your Container

According to the Department of Energy, R-value is a measurement of insulation resistance to heat flow. Higher R-value usually means better insulation, but thicker insulation takes up more interior space.

Typical ranges for insulated shipping container builds:

- Mild climates: R-10 to R-20

- Hot climates: R-15 to R-25 (roof especially important)

- Cold climates: R-20 to R-35 (walls + roof)

Your ceiling and roof insulation often deliver the biggest payoff because the roof receives direct sunlight and radiant heat.

Best Way to Insulate a Shipping Container

Dry Box offers multiple professional-grade insulation systems to match different budgets and goals.

The best way to insulate a shipping container depends on how you plan to use the space and what kind of performance you want.

Each option has specific strengths and tradeoffs, so let's take a look at the most effective options offered by Dry Box.

Contact us for more information on Dry Box insulation options.

1) Fiberglass Insulation

Fiberglass insulation is one of the most common materials used in traditional construction, and it can also work well inside insulated shipping containers when installed correctly.

This option is a practical choice for customers who want solid thermal performance at a budget-friendly price, especially for basic container conversions that do not require premium air-sealing.

Pros

- Affordable and widely available

- Easy to install inside framed walls

- Provides good overall insulation value

- Works well in combination with metal building insulation methods

Cons

- Requires proper framing to hold it in place

- Can lose performance if it gets wet from condensation

- Does not seal air leaks on its own

- Can sag or compress over time if installed poorly

Fiberglass can be a reliable option for shipping container insulation, especially when paired with good sealing, ventilation, and a clean interior finish.

For many builds, it provides a straightforward balance of cost and performance while still supporting a comfortable, usable interior space.

2) Insulated Foam Board (Rigid Insulation Foam)

Rigid insulated foam boards are a popular solution for container conversions because they provide high insulation value in a slim profile. Foam board is also lightweight and easy to cut around framing.

Foam board is a great match for projects that want consistent insulation coverage without the higher price of spray foam systems.

Pros

- High insulation value per inch

- Clean install with minimal mess

- Helps reduce radiant heat transfer

- Works well with finished interior walls

Cons

- Gaps between panels reduce performance if not sealed

- Requires careful cutting for tight fit

- Less effective for odd shapes and corrugations

- Needs a solid vapor control plan in some climates

Foam board is one of the most practical shipping container insulation options when you want a strong balance of performance and cost.

3) Rock Wool or Mineral Wool Insulation

Rock wool, also called mineral wool, is a durable insulation material made from spun mineral fibers. It is known for strong thermal performance and excellent fire resistance.

It also performs well as soundproof insulation, making it a popular choice for offices and workspaces.

This is a great metal building insulation option because it performs well in steel structures when installed correctly with framing.

Pros

- Excellent sound absorption and noise control

- Strong fire resistance and heat tolerance

- Resistant to sagging over time when installed properly

- Works well in framed cavities

Cons

- Needs wall framing to hold it in place

- Does not air-seal on its own

- Can absorb moisture if exposed to leaks

- Requires a good vapor and airflow strategy

If you care about noise reduction, mineral wool insulation can be one of the most effective materials for a container build.

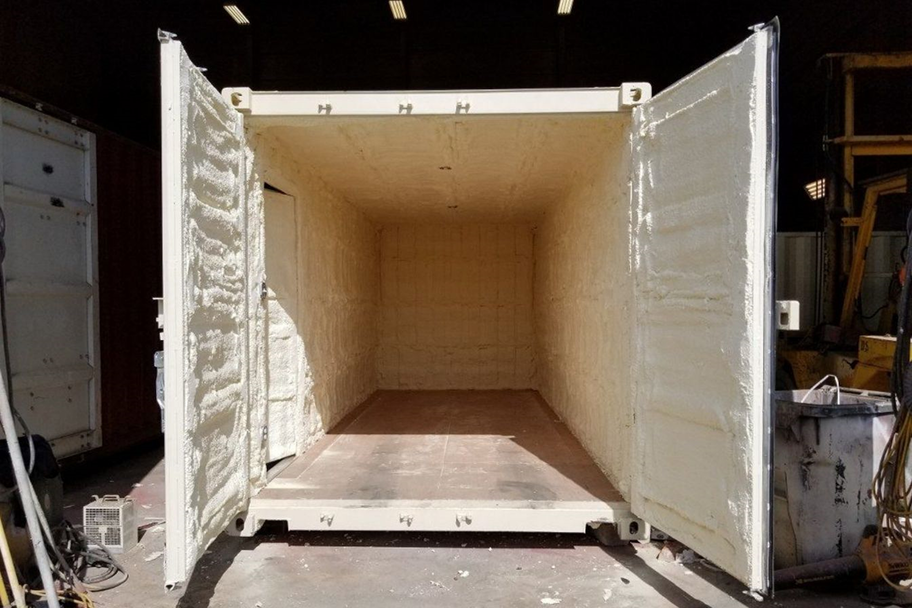

4) Closed Cell Spray Foam Insulation for Shipping Containers

Closed cell spray foam is often considered the top-tier solution for container insulation. It expands to fill gaps and bonds directly to steel walls, helping prevent air leaks and reducing condensation risk. It also adds rigidity and strength to surfaces.

For many customers, this is the best way to insulate a shipping container because it combines insulation and air sealing in one system.

Pros

- Seals cracks and gaps automatically

- Strong moisture resistance

- High R-value performance

- Great for corrugated steel walls

- Reduces condensation better than many alternatives

Cons

- Higher upfront price than other options

- Installation is more permanent

- Must be applied correctly for consistent coverage

- Can reduce interior space slightly depending on thickness

What does spray foam insulation cost?

Spray foam insulation cost depends on thickness, total square footage, and local labor rates.

Closed cell foam usually costs more than foam board or mineral wool, but it often delivers better long-term value by improving energy efficiency and preventing moisture issues.

If you want the most complete insulation system with the fewest weak spots, closed cell spray foam is hard to beat.

Common Mistakes When Insulating a Shipping Container

A shipping container can be incredibly comfortable and efficient, but only if the insulation is installed the right way.

One of the most common mistakes is leaving small gaps in coverage, which can create cold spots, moisture issues, and uneven temperatures inside the space.

The shipping container roof is another area people often overlook, even though it takes the most direct heat from the sun.

Moisture problems can also happen when wall panels trap humidity against the steel or when insulation is installed over rust or damp surfaces.

Skipping air sealing around doors and cutouts is another issue. The best results come from planning the full insulation system based on your climate and intended use.

Shipping Container Insulation Cost From Dry Box

Dry Box charges around $7500 to insulate a 20ft shipping container with studs and sheeting.

If you need help selecting the right insulation package, Dry Box can match the right build style to your location, budget, and goals.

Frequently Asked Questions About Insulating a Shipping Container

How do you insulate a shipping container properly?

Insulating a shipping container properly starts with preparing the interior, sealing air gaps, and choosing the right insulation type

for your climate and use. The insulation should fully cover walls and the ceiling to reduce heat transfer and condensation.

What is the best insulation for a shipping container?

The best insulation depends on your goals and budget. Spray foam offers the highest performance and moisture control, while foam board,

fiberglass, and mineral wool provide effective alternatives for different build types.

Do shipping containers need insulation?

Yes, shipping containers need insulation to control temperature, prevent condensation, and protect

the steel structure. Without insulation, the interior becomes uncomfortable and can trap moisture that leads to rust.

How much does spray foam insulation for shipping containers cost?

Spray foam insulation cost varies based on container size, thickness,

and labor rates. It typically costs more upfront than other options but delivers better long-term energy efficiency and moisture

protection.

Can I insulate a shipping container myself?

Some insulation types like foam board and fiberglass can be installed by experienced DIY

builders. Spray foam insulation usually requires professional equipment and training for safe, consistent application.

How do I prevent condensation inside a shipping container?

Condensation is reduced by sealing air leaks, controlling humidity, and using

insulation that limits air movement. Proper ventilation and moisture-resistant insulation systems also help prevent interior sweating.

What R-value insulation do I need for a shipping container?

The required R-value depends on your climate and how the container will be

used. Mild climates may need lower R-values, while hot or cold regions benefit from higher insulation levels, especially in the roof.