5 Ways To Ventilate a Shipping Container

A shipping container is built to be watertight and weatherproof, which makes it excellent for transporting goods, but air circulation must be considered.

Standard shipping containers are excellent as a storage shed alternative. However, when you turn a container into a workshop, office, or tiny home, trapped heat and moisture become things to think about.

Without proper ventilation in certain conditions, condensation can form on the steel walls, mildew can spread, and the interior can reach quite high temperatures.

There are several different types of container ventilation to prevent that. This article shows you 5 easy ways to ventilate a shipping container.

Why Shipping Container Ventilation Matters

If you've ever opened a sealed container on a hot day, you already know how quickly the temperature and humidity can spike.

Effective container venting is what turns a sealed shipping container, great for storage, into a livable, breathable, and sustainable space.

Good shipping container ventilation prevents those problems before they start. OSHA recommends adding additional ventilation if you spend time in the container or if hazardous substances such as dusts, fumes, mists, vapors, or gases exist.

Proper ventilation keeps the air fresh, protects valuables from rust and mold in the long term, and creates a safe and comfortable environment for people and goods alike.

When Ventilating a Shipping Container Is Most Important

Ventilation is critical in hot and humid climates and in many real-world uses. Containers that store sensitive materials, electronics, or furniture need airflow to prevent condensation damage.

When a container is repurposed as an office or home, ventilation is essential for comfort and safety.

Common use cases include:

- Long-term storage of equipment or household items (like motorcycle storage)

- Containers converted into offices, workshops, or retail kiosks

- Tiny homes, cabins, or guest units

- Food storage, refrigeration prep, or vineyard operations

- Agricultural and farm supply storage like container barns

- Disaster-relief and emergency response units

Each situation has different ventilation needs, but the goal is always the same: let fresh air in, move stale air out, and control temperature and moisture.

5 Container Venting Options

There are 5 proven ways to ventilate a shipping container:

- Passive air vents

- Powered vents or exhaust fans

- Windows

- Doors

- HVAC systems

Passive Shipping Container Air Vents

The most straightforward approach to container ventilation is the installation of passive air vents. These rely on natural air movement without electricity or mechanical system required. The three most common types are standard container vents, louvered vents and turbine vents.

Standard Shipping Container Vents

When you buy or rent a shipping container, they typically come with two standard vents which help depressurize the container in certain conditions in order to protect contents. They also allow some minimal airflow and release of heat and humidity.

These factory-installed vents are sufficient for temporary transportation or storing durable items in mild climates. However, standard shipping container vents may not be sufficient for keeping sensitive items safe in hot, humid climates.

Adding additional container venting like more standard vents, or louver or turbine vents works to create enough airflow to maintain safe temps for most storage items.

Louvered Vents For Containers

Louver shipping container vents are ideal because they're easy to install, don't require electricity, and allow hot air to escape while maintaining the water-tightness for the container.

Louver vents are typically around 12” x 12” slanted metal covers that allow airflow while blocking rain and debris. They're often mounted high on the sidewalls or doors of the container.

They prevent stagnant air pockets and help equalize temperature inside and outside. Over time, this minimizes condensation which is the number-one cause of corrosion and odor inside steel containers.

Two louver vents per container is recommended to maximize airflow. Vents should be placed on opposite walls and at different heights. A low vent brings in cooler outside air, while a higher vent releases warmer air that rises naturally.

For small storage uses, this passive approach often provides enough circulation to protect stored items year-round.

Turbine Vents

Turbine vents for storage containers are also a passive ventilation solution that doesn't require electricity.

A turbine vent is a wind-driven vent that allows warm air to escape from the top of the container. As the hot air exits, cooler air gets drawn in through lower side vents, creating a natural convection effect.

Turbine vents are popular because they work with the wind, spinning to exhaust air even when the container isn't powered.

Exhaust Fan Systems For Shipping Containers

In hot and humid climates, where passive container vents may be insufficient for your use case, powered roof vents and attic exhaust fans may be preferable when electricity is readily available. There are also solar powered attic fans that may work for offgrid situations.

These active systems move large volumes of air quickly and keep heat from building up near the ceiling.

For more control, an attic exhaust fan system can be installed. This includes an electric or solar-powered fan mounted on the roof or upper wall, sometimes paired with a thermostat or humidity sensor.

The fan activates automatically when temperatures rise or when the air gets too moist. These fan-kit systems are especially effective for containers used as offices, studios, or living spaces.

By constantly pulling warm, humid air out, you can maintain a more stable temperature and prevent condensation on the container ceiling. The fan, when combined with intake vents below, creates a full air-exchange cycle that keeps the interior dry and balanced throughout the seasons.

Windows For Container Ventilation

Beyond vents and fans, adding windows to a shipping container is one of the most natural ways to improve airflow and comfort. Shipping container windows allow you to control air circulation and daylight while enhancing livability and reducing the need for mechanical ventilation.

When placed strategically, they create an effective cross-breeze that moves hot air out and draws in cooler air. For containers converted into mobile offices, studios, or container cabins, windows are essential for natural light, regulating temperature and preventing stale air.

Casement or sliding windows work best because they can be opened partially or fully depending on the weather. Installing windows also increases visibility and connection to the outside environment, which improves comfort for people working or living inside the container. Screens or shutters can be added to keep bugs and moisture out.

Cargo Container Doors

Doors are another powerful tool for improving shipping container ventilation. There are several types of shipping container doors. Each is useful for helping to ventilate the container.

Standard cargo doors, roll-up doors or man doors create openings that allow rapid air exchange. When both ends of a container are equipped with doors, a natural tunnel effect occurs where fresh air flows through and stale air escapes easily.

This cross-flow helps remove humidity, fumes, or lingering odors, especially in workshop or storage applications. Cargo doors can also be modified with louver vents to provide consistent airflow even when closed.

If you're converting a container for human use, adding a man door or double-French doors improves both convenience and ventilation. Choosing doors with windows or glass inserts lets in light while maintaining airflow when open.

For long-term use, installing a door seal system helps prevent leaks without restricting ventilation. Combined with side vents or a roof fan, doors play a vital role in achieving balanced container venting, turning a static unit into a dynamic, breathable space.

Climate Control Systems

If your project demands more than passive airflow or fans can provide, it's time to integrate full climate control options. The experts at Dry Box explain that effective container climate control combines ventilation, insulation, and temperature management into a complete system.

An air-conditioning or heat-pump unit not only manages temperature but also removes humidity from the air. These systems can be mounted through the wall or integrated with ducting and thermostat controls.

When paired with insulated walls and ceilings, an AC or heat pump keeps the interior comfortable year-round while protecting sensitive items from thermal stress.

Insulation is just as important as airflow. It stabilizes temperature, reduces condensation, and helps the container ventilation system perform efficiently. Common materials include fiberglass, spray foam, and rigid foam board.

Proper sealing around doors, vents, and windows ensures that your fan or HVAC system can control airflow effectively instead of battling leaks

In a full-scale installation, you might have:

- Two or more intake vents low on the sidewalls

- One exhaust vent or attic fan on the roof

- Insulated walls and ceiling

- A climate control unit with thermostat and dehumidifier

- Doors or windows positioned for cross-flow

Together, these components create a balanced ecosystem inside your container including fresh air, controlled humidity, and consistent temperature. This “fan, kit, and system” combination is ideal for high-value storage, mobile offices, or living spaces where comfort and protection are priorities.

How to Ventilate a Shipping Container: Step-by-Step

Dry Box offers modified shipping containers for sale with any of these ventilation options, but first you need to evaluate your needs.

To make your own plan for how to ventilate a shipping container, start by identifying what's inside and how it will be used. If it's short-term storage for tools or seasonal items, basic vents might be all you need. But if you're storing furniture, food, or electronics or converting it into an occupied space, you'll want a more advanced setup.

To develop your ventilation plan, follow these steps:

- Assess your existing venting. Most containers come with small factory vents that allow minimal airflow but are rarely enough for anything beyond dry storage. Adding two or more upgraded vents improves the air exchange rate dramatically.

- Decide on your airflow type: passive, active, or full climate control. A passive setup uses only vents. An active system adds a fan. A complete system integrates insulation, HVAC, and humidity controls.

- Install your vents and fans strategically. Put one intake low and one exhaust high. And make sure the pathway between them is clear of shelves or boxes.

- Test and maintain your system. Inspect vents regularly to make sure they're not blocked by debris, insects, or rust.

Check for condensation on walls or ceilings, which could indicate insufficient airflow. For powered fans, confirm that wiring, thermostats, and blades are clean and functional.

If you're using your container for storage, start with quality shipping container air vents. If you're living or working inside it, install a roof fan or attic exhaust system. And for climate-sensitive applications, invest in insulation and a complete container ventilation system with heating and cooling.

Good airflow means dry walls, stable temperatures, and healthy air. Whatever your use, ventilation is the key to unlocking your container's full potential.

How to Ventilate a Shipping Container: Step-by-Step

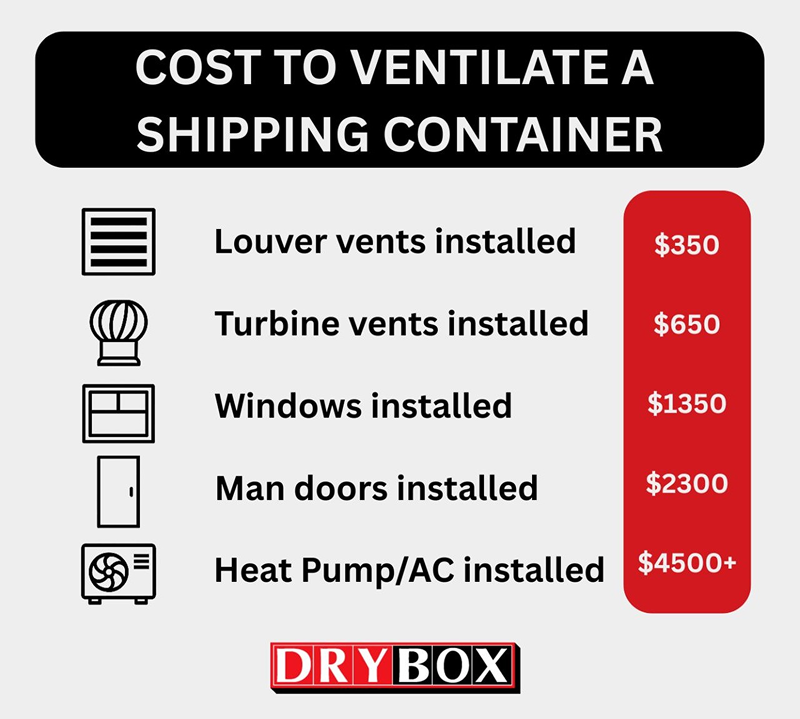

The cost to ventilate a shipping container can range from very low for DIY options to several thousand if you want doors installed or HVAC stems with insulation.

Here is a general idea of container venting costs:

- Small container vents cost around $20 on Amazon for an 8-pack. (Cheapest option if you install them yourself.)

- Louver vents installed by Dry Box cost around $350

- Turbine vents installed by Dry Box cost around $650

- Windows installed by Dry Box cost around $1350

- Man doors installed by Dry Box cost around $2300

- Heat pump/ACs installed by Dry Box range from $4500-$6500 (depending on size)