How To Put a Man Door in a Shipping Container

Adding a personnel door to a container is one of the most valuable upgrades you can make. A shipping container man door increases convenience, improves workflow, and helps transform a steel container into a functional structure.

Many people want to know how to put a man door in a shipping container because it creates fast access without opening full cargo doors.

This guide covers the use cases, door types, tools, and the full step-by-step process to install a man door in a shipping container correctly and safely.

Why Add a Man Door for Shipping Containers?

When used for storage, workshops, business spaces, offices, tiny homes, or jobsite structures, a cargo container man door becomes essential.

Factory cargo doors are secure but heavy, not ideal for daily use. High quality shipping container man doors solve that problem by giving you fast access and controlled entry.

Below are the most common use cases that benefit from a man door installation.

Use Cases Where a Shipping Container Man Door Is Valuable

-

Storage Containers for Personal or Business Items

Opening full cargo doors every day becomes inconvenient. A personnel door for a shipping container shed lets you grab items quickly and keeps the container more secure because you only open a small entry point. -

Construction Offices and Jobsite Workshops

Project managers, contractors, and technicians use containers as mobile offices and guard shacks. A shipping container entry door creates a normal entrance that improves workflow and traffic flow. -

Retail Spaces and Pop-Up Shops

Converted shipping containers with side doors and a man door allow customers to walk in naturally. The layout feels closer to a traditional storefront. -

Container Homes, Cabins, and ADUs

A man door for a shipping container cabin is essential for any container used as a living space. It allows standard movement, daylight, insulation, and improved ventilation. -

Climate Controlled Storage or Cold Storage Containers

Units with insulation and climate systems do best with man doors that seal tightly. This helps the container hold consistent temperatures. See refrigerated containers here. -

Gyms, Studios, and Hobby Rooms

A man door makes the space feel more like a permanent building and creates smoother daily access. -

Hybrid Workshops with Multiple Entry Points

Some containers already include side openings, roll up doors, or shipping containers with side doors. Adding a man door gives you even more utility based on how you use the space.

Shipping Container Man Door Options

Not all doors will work on steel containers. Shipping containers flex slightly, are very rigid in some areas, and need a reinforced frame when cut.

The best choices are designed for steel structures and heavy daily use:

-

Steel Personnel Doors

These are the most common options. They are durable, secure, and weather resistant. Most shipping container man door kit packages include a pre-hung steel door with a reinforced steel frame. -

Insulated Man Doors

Insulated doors help stabilize interior temperatures and reduce condensation. These are ideal for offices, living spaces, and climate controlled containers. -

Commercial Grade Fire Rated Doors

If you plan to use the container indoors or in a commercial setting, a fire-rated door may be required. These are very durable and safe. -

Security Doors

Heavy duty steel doors with upgraded locks and reinforced cores are perfect for high value storage and equipment shelters. - Prehung Doors in Container-Ready Frames brThese are the easiest to install because the frame is already sized for container walls. Many shipping container entry doors include steel studs, trim rings, and mounting brackets.

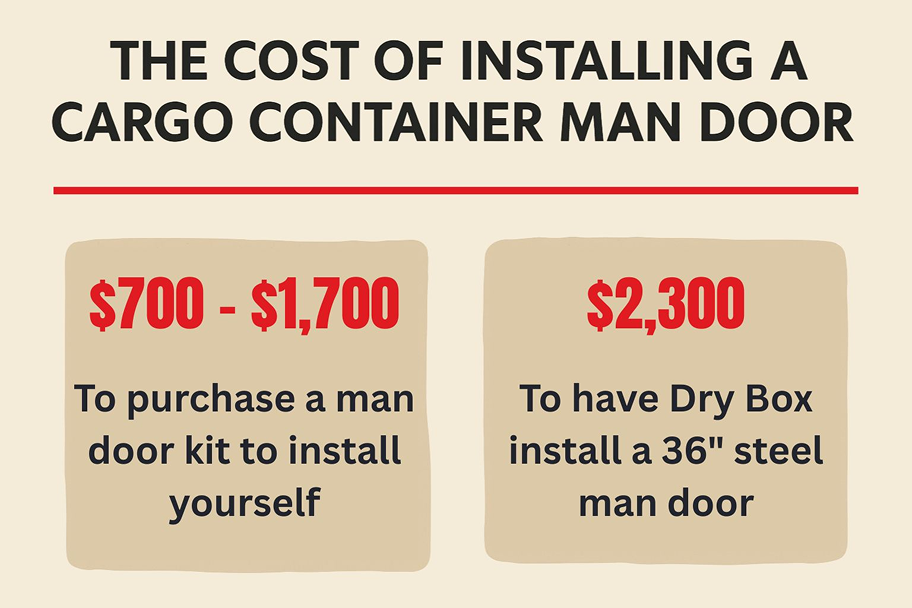

The Cost to Install a Cargo Container Man Door

The price to install a cargo container man door varies based on the type of door you choose, the level of reinforcement required, and the container's condition.

Most professional installations fall within a range of $1,800 to $3,500, with insulated or commercial-grade doors costing more. Installation kits can range from $700 to $1,700 if you're handy and have the equipment to do the work yourself.

Dry Box offers shipping container modifications like adding a 36 inch steel man door and charges $2,300 for a full installation in one of our containers.

This price includes cutting, welding in a reinforced steel frame, installing the pre-hung door, sealing the perimeter, and finishing the area

Dry Box Container Man Door Specs:

- 18g Steel Door Construction

- 3' wide 6'8 tall (36"x80")

- Tamper Proof Knurled Hinges

- Keyed-Alike Dead Bolt and Door Knob

- 2" Tube Steel Frame

For customers who buy a shipping container and want a secure, clean, and reliable installation, this provides strong value compared to DIY options that require specialized tools and metalworking knowledge.

What's Needed to Install a Man Door in a Shipping Container

Before you learn how to put a man door in a shipping container, gather the correct tools. Cutting steel requires the right safety equipment and proper power tools.

Do not attempt this installation yourself unless you have safety training with this equipment.

Always consult a certified professional before considering any man door addition to your shipping container. Make sure protective equipment is used at all times.

Tools:- Angle grinder with metal cutoff wheels

- Plasma cutter or reciprocating saw with metal blades

- Measuring tape

- Level

- Welder (MIG is most common)

- Drill with metal bits

- Clamps

- Marker or chalk line

- Safety glasses, gloves, and hearing protection

- A shipping container man door kit or stand-alone personnel door

- Steel studs or square tube framing for reinforcement

- Weld-on hinges if installing custom

- Exterior grade caulk or sealant

- Rust resistant primer and paint

- Foam insulation (optional)

- Weather Stripping

Step by Step: How to Put a Man Door in a Shipping Container

The following steps provide a clear and simple method to install a man door in a shipping container. This approach works for both custom builds and prehung door kits.

Step 1: Pick the Right Location

Choose a location on the container wall that is free of structural beams. Shipping containers have vertical corrugated panels and horizontal ribs.

Avoid cutting into corner posts, top rails, or bottom rails. Pick a spot that creates useful access for your layout.

Step 2: Measure and Mark the Opening

Use the dimensions of your cargo container man door and mark the cut lines. A standard man door is usually 36 inches wide by 80 inches tall, but container doors often require slightly different sizing based on the frame.

Use a level to verify everything is straight. A square opening makes the install easier and prevents binding.

Step 3: Cut the Wall Opening

Use an angle grinder, plasma cutter, or reciprocating saw to cut along your marked lines. Cut slowly and allow the tool to do the work.

Dry Box installs man doors that are 36" wide x 80" tall with a 2" frame. So our fabricators cut 40" x 82" plus 1/8” for placement.

Once the panel drops free, clean all sharp edges. Removing burrs helps the frame sit correctly and reduces risk of injury.

Step 4: Weld Reinforcement Around the Opening

This is one of the most important steps in the entire process.

Containers rely on their corrugated walls for structural rigidity. When you remove a section, you must reinforce the opening with steel tubing or studs.

Build a rectangular steel frame that matches your cutout. Weld this frame into place around the entire opening. This forms a strong and stable support that prevents twisting and sagging.

Many shipping container man door kit packages include this frame ready to weld.

Step 5: Test Fit the Door

Before installing, place the man door into the opening to confirm alignment. Check for gaps, uneven spacing, or misalignment. Adjust the frame if needed.

This step prevents installation issues later.

Step 6: Install the Door Frame

If you are using a pre-hung door, place the full unit into the opening and secure it with clamps. Drill mounting holes and fasten the door frame to the reinforcement frame.

For custom doors, weld or bolt the hinges directly to the frame. Make sure the door swings freely.

Step 7: Install the Door and Hardware

Attach the door slab to the hinges, install the handle, lockset, and weatherstripping. A strong lock improves security and protects valuable items

Check for smooth operation before sealing the edges.

Step 8: Seal the Frame

Use exterior grade caulk or sealant around all edges of the door frame. This prevents water from entering the container. Containers are designed to be watertight, so proper sealing keeps the interior dry.

If you plan to insulate the container, add foam insulation around the frame before adding interior walls.

Step 9: Paint and Finish the Area

Prime any exposed metal and apply exterior paint to protect against rust. Many owners match the door color to the container for a clean look.

This is also a good time to add steps, lighting, or a container canopy outside the door.

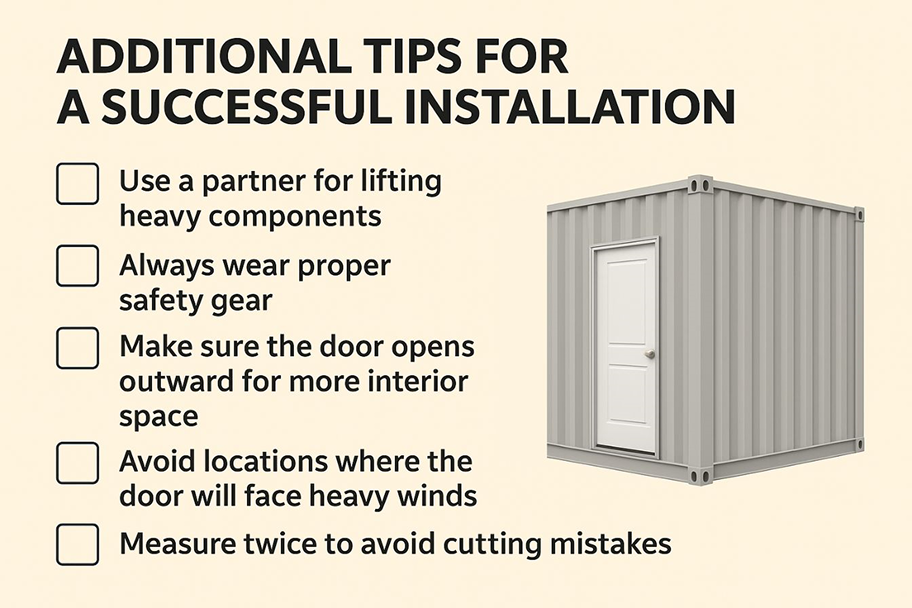

Additional Tips for a Successful Installation

- Always refer to international building codes before attempting an installation - IBC chapter 31 and ISO 1496-1 defines how a man door should be installed

- Use a partner for lifting heavy components

- Always wear proper safety gear

- Make sure the door opens outward for more interior space

- Avoid locations where the door will face heavy winds

- Measure twice to avoid cutting mistakes

Final Thoughts on How to Put a Man Door in a Shipping Container

Learning how to put a man door in a shipping container allows you to transform a steel box into a fully functional workspace, home, office, or storage room.

With the right shipping container door, proper reinforcement, and correct installation steps, your container will perform like a traditional structure while retaining the strength of steel.

If you want the most convenient entry, combine your man door with shipping containers with side doors or roll up doors for maximum flexibility. A properly installed door makes every container more practical, more valuable, and easier to use every day.

Safety Disclaimer

This article is for informational purposes only. Cutting or modifying a shipping container involves significant risks. Always follow safety guidelines and consult qualified professionals. The authors and publisher do not recommend attempting this installation yourself, and are not responsible for injuries, damages, or losses resulting from the use or misuse of this information.