Defining Hard Top and Soft Top Containers

You have a lot of choices when it comes to shipping containers. There are two main choices: hard top and soft top (which can include open top).

Hard top containers are one of the most common options in the shipping industry for their versatility, durability and longevity. These specialized versions of standard dry containers do so much more. They are made for multi-purpose uses, which makes them especially ideal for ever-changing, dynamic industries.

You can ship dry cargo, oversized cargo and bulky cargo in a hard top container, which is a specialized intermodal container with a removable roof. They are structurally similar to a standard container, but because the roof can be removed, the unit is capable of shipping heavy, oversized, and odd-shaped cargo that must be placed inside from the top.

Soft top containers are also popular when it comes to shipping awkward shaped cargo that can’t be constrained with a hard top. They are known as specialty units, but have similar storage and transport purposes as standard hard top shipping containers. They are able to accommodate much larger items, usually those that can’t be loaded into a standard shipping container.

Let’s go over the differences between the two types.

Hard Top Containers

The big advantage to hard top containers is that they can accommodate cargo height that exceeds the height of the roof. This is often the case for construction or automotive companies who have to store or ship oversized vehicles or pieces of machinery.

You can simply lash the detachable roof to the sidewall inside the container to cover the cargo so it won’t be impacted by the elements or any falling debris. Take it off again and voila – you have an open-top container. This is why hard top containers are so popular – their versatility makes them sought-after by freight forwarders who have to present flexible options to their clients.

Likewise, they are ideal for manufacturing companies that import raw materials and export finished goods because their cargo size is always different.

Characteristics

There are many special features of hard top containers, which are made of corrugated steel. The floors are made of wood to lessen friction. Most such units have rings or pockets on the roof so they can be lifted off easily.

To secure cargo inside the container, there are lashing rings in the lower and upper side rails, corner posts, and middle of the sidewalls that can be utilized. Also, on hard top containers, the door header pivots outside, making it simple to unload and load cargo via a forklift.

Cargo

In a hard top container, you can store general dry cargo when the roof is on. When the roof is off, you can store bulk cargo such as steel, cement, automotive parts, construction goods, machinery and more.

Hard top containers are great for heavy goods and heightened cargo that can only be loaded through the top with a crane, forklift, or crab. Such fragile cargo can include glass sheets, marble slabs, raw materials such as coal, and large machinery. Additionally, just to put it into perspective, you can fit 25 pallets inside.

Sizes and Dimensions

Hard top containers are available in standard sizes that are set by the International Organization for Standardization (ISO). The typical sizes include 20ft, 40ft, and 40ft high cube containers.

Soft Top Containers

These are made from corrugated steel, whereby the top is open and covered with a tarp or some kind of soft roof. The tarp is secured to the container with removable bows. This allows you to swing the roof away so you can easily add cargo to the shipping container.

You can use the end doors as well for easier loading. Dimensions and sizes will vary, but you will enjoy a larger capacity because you are not restricted by a solid roof.

Uses

These are best for loading scrap metal and timber using cranes that drop those items into the top of the container. This makes it easier to load and unload cargo. Even if over-height when fully loaded, the soft covering means you don’t have to designate another special storage area for your stuff.

Oversized tarps can be made to order. Just tell your shipping provider the dimensions of your over height cargo so they can match you with the best covering for adequate coverage. Lashing rings secure the tarp so the cargo is safe and stable for the trip.

Most open top or soft top containers are 40 feet long, but they also come in 20-foot sizes. Common things you can store in an open top or soft top container include:

- Raw mining materials

- Pipes

- Cable spools and cables

- Tools

- Logs, machinery, scrap metal, and oddly-shaped items

- Machinery attachments

- Construction supplies/debris

- Tall, awkward or bulky cargo

Basically, if you have items that are bigger than what may be reasonably stored inside a standard container, you will need this type of unit.

They’re pretty convenient to use when the primary material handling equipment you need on your site is only accessible by crane.

If you need something higher, high cube open top shipping containers are available. With modified open top shipping containers, these are created not just by cutting the steel roof off a traditional container. They will require additional structural supports that would otherwise be provided with a roof.

Modified open tops feature a lower overall capacity, don’t have the best resale value, and they have more restrictions on loading and handling. That said, they’re more affordable than original factory-built soft top or open top containers, and you can get them for specific locations and specific times.

No matter which kind you need, your shipping container provider should be able to match you with the best one for your budget and requirements.

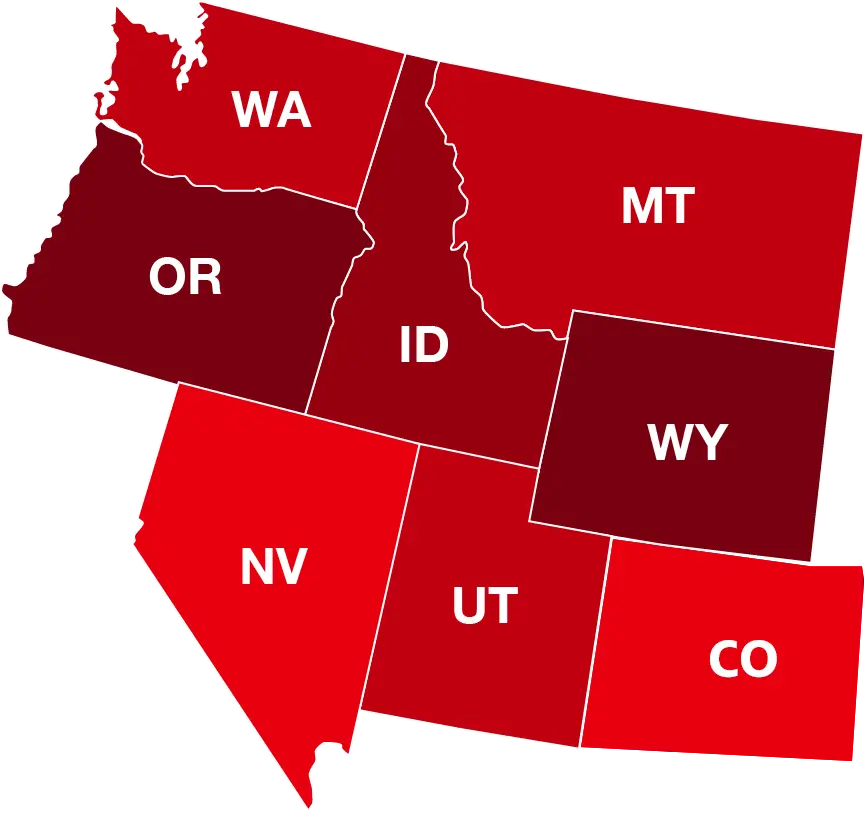

Contact DRY BOX

To learn more about the difference between hard and soft top containers, and to get advice on the best one for you, contact us at 866-549-9823.